-

-

Favorites No products

-

Comparison No products

-

My basket0 Your shopping cart is empty

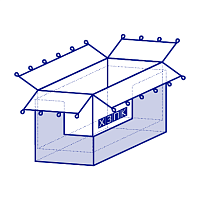

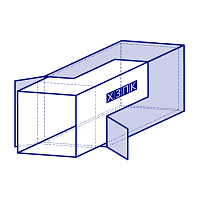

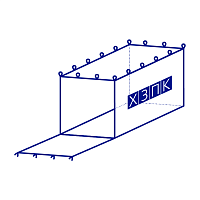

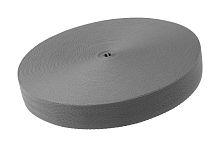

Tubular PE film

Polyethylene tubular film is one of the demanded subtypes of PE films. It has found a wide range of applications as packaging material for production of food and non-food industries. Its popularity is also explained by the cost price, which is pleasant for the accounting.

Production stages of PE tubular

Kharkiv Plant “Polymercontainer” produces PE tubular film by extrusion on modern equipment, which ensures high quality of finished goods. The base raw material is a granule of primary or secondary (recycled) polyethylene.

The granular material is loaded into the hopper of the extruder, where it is melted to a viscous consistency under the action of high temperatures (about 180-200 °C). After, it is literally “pulled” through the ring system of equipment. Ultimately, the polyethylene mass takes on a balloon-like shape. A tubular film is formed, which after the cooling stage is wound on a spool.

Application areas of PE tubular film

Polymer tubular film is perfect both for single-piece and for group packaging of products. Due to this, polyethylene film can be found in the following industries:

-

Food industry;

-

Construction industry;

-

Agriculture;

-

Medicine;

-

Chemical industry;

-

Typography;

-

Biofuels etc.

KhPPC as a manufacturing plant can approach to the production of films for individually each order. Client just needs to decide on the following parameters:

• Sizes: Width × Thickness (from 20 to 200 μm);

• Source material: primary, secondary, composite;

• Film color: transparent or with paint pigments;

• Type of polyethylene: LDPE, HDPE, MDPE;

High-pressure polyethylene (LDPE) is flexible and soft by touch. It has a glossy presentable look. At the same time, LDPE has a high material strength and resistance to mechanical damage and stretching.

Polyethylene tubular film produced by KhPPC is quality at a favorable price!

Have you decided to buy a plastic tubular film? Leave a request on the website or contact the manager directly!

Catalog

Catalog .jpg)

Calculate

Calculate Kupuj za jednym kliknięciem

Kupuj za jednym kliknięciem Porównanie

Porównanie Dodaj do ulubionych

Dodaj do ulubionych Na zamówienie

Na zamówienie

Cena na żądanie

Cena na żądanie

.jpg)

.png)