-

-

Favorites No products

-

Comparison No products

-

My basket0 Your shopping cart is empty

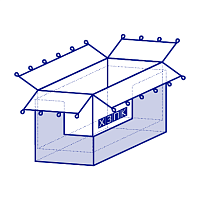

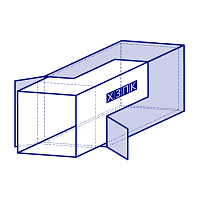

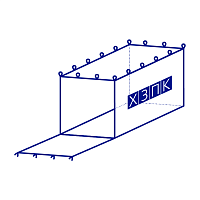

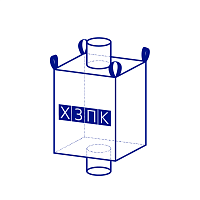

1 loop Fibc Big Bag

1-loop flexible containers (FIBC/Big Bags) are made of polypropylene fabric of different density, from 60 up to 250 g/m2. The higher the density of selected fabric, the more resistant a Big Bag becomes to wear and tear. For additional protection from air/moisture, the main material of container goes through a lamination process. If the transported cargo, on the contrary, needs to be ventilated, then non-laminated fabric is used.

The loop of this Big Bag comes out of the material of container itself, as its extension. The standard loop length is 45 to 60 cm. The sling has a brightly colored cuff for clear visibility by a crane operator or loader. In addition, the cuff protects the container from mechanical damage during direct cargo transportation.

Kharkiv Plant “Polymercontainer” produces one-loop Big Bags for the needs of various companies, from agriculture to the chemical industry.

Commonly used sizes:

Bottom: 75 to 75, 90 to 90, 95 to 95 cm

Height: 90 to 190 cm

To choose the needed container variation, you can use the constructor on our website and the manager will give feedback within a few hours according to your request!

KhPPC provide various options of modifying Big-Bag containers:

-

Open top;

-

Plain bottom;

-

Duffle top;

-

Filling/Discharge spouts;

-

Protection flaps etc.

Among the advantages of FIBC using are the following:

-

Ability to load a wide range of materials from the food and non-food industries;

-

Availability of various containers’ configurations for the needs of the client;

-

Advantageous correlation of price and quality;

-

Low packing weight, taking into account carrying capacity up to 2 tons;

-

Possibility of recycling and multiple use;

-

Protection of cargo and minimization of its losses at all stages of circulation;

-

Increasing the speed of filling and discharge operations;

-

Safety of the environment.

Choosing a one-loop container manufactured by the Kharkiv Plant “Polymercontainer”, you will be convinced of the quality of its characteristics!

Catalog

Catalog .jpg)

Calculate

Calculate Kupuj za jednym kliknięciem

Kupuj za jednym kliknięciem Porównanie

Porównanie Dodaj do ulubionych

Dodaj do ulubionych Na zamówienie

Na zamówienie

.png)